Contact

314.421.5933

Address

500 S Ewing Ave, Suite G

St. Louis, MO 63103

Every Keeley'n. Every Action. Every Time.

Construction Quality Management

EMBRACING EXCELLENCE

Culture of Quality

Quality is defined as “conformance to requirements”. At Keeley Construction, we believe in taking that one step further by creating a culture around quality that influences every Keeley'n, every action, every time. We set the benchmark for quality on every project and hold our sub-partners to our quality expectations. Our Quality Program is structured to help our team and subcontractors identify the appropriate requirements to ensure compliance, avoid rework, and exceed our client's expectations. We strive to complete our work right the first time.

EXCELLENCE DEFINed

Our Quality Values

Consistent with our Mission and Values, it is our policy to provide clients with innovative construction services that meet the project standards for work practice and customer service, at the highest levels of quality. Keeley’s project teams are responsible for fostering a climate of continuous improvement and are empowered to suggest appropriate changes to achieve this goal.

PREPaRATION

Preparation is crucial in implementing a construction quality program, as it involves thorough planning, identification of potential risks and hazards, and ensuring that all necessary resources and personnel are in place.

COMMUNICATION

Effective communication is essential in a construction quality program to ensure that all stakeholders are informed of quality standards, procedures, and expectations, and to facilitate collaboration and timely resolution of any quality issues.

VERIFICATION

Verification plays a vital role in any construction quality program, as it encompasses a series of essential activities such as inspections, tests, and audits. These guarantee that our work aligns with the prescribed quality requirements and industry standards.

DOCUMENTATION

Documentation is a key element of a construction quality program as it involves the systematic recording and storage of information related to quality management activities, which can provide evidence of compliance and serve as a reference for future projects.

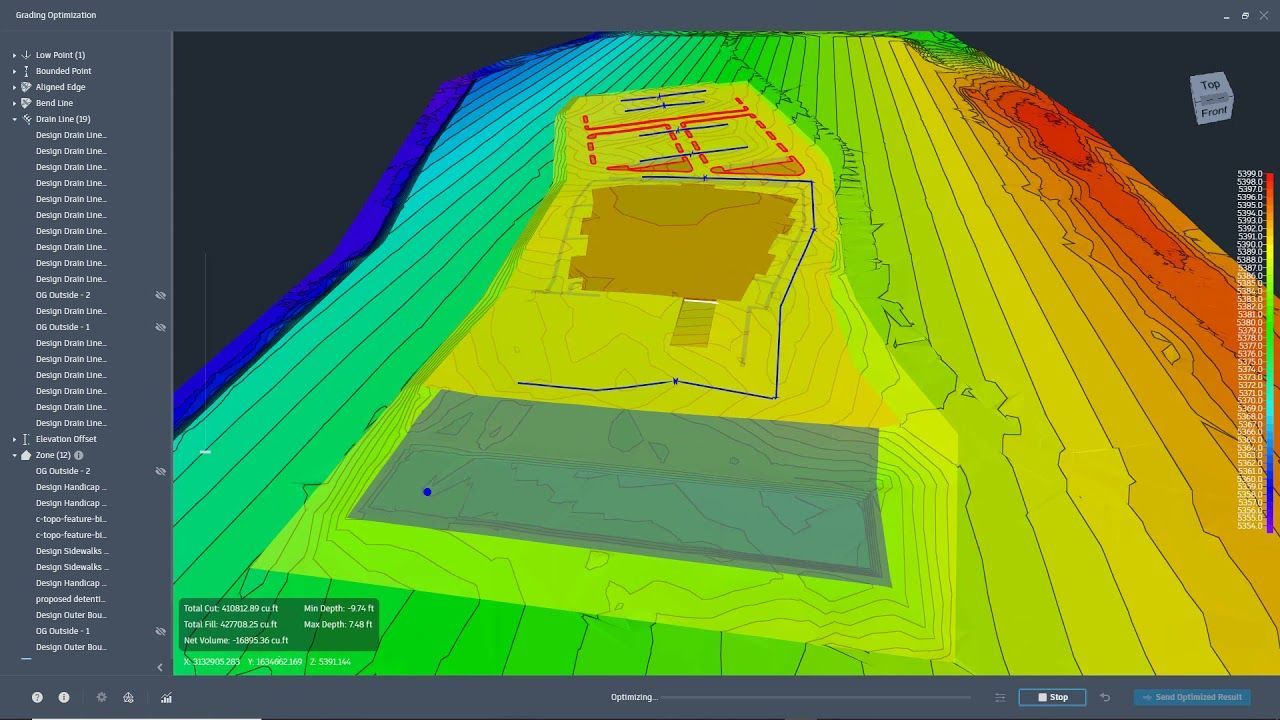

Mapping Tomorrow, Today

Geospatial Capabilities

We harness cutting-edge geospatial mapping capabilities to ensure every project is executed with precision and efficiency. Our advanced mapping technology allows us to visualize, analyze, and optimize site conditions, resulting in seamless project planning and execution. By leveraging geospatial mapping, we uphold our commitment to safety, quality, and innovation, setting us apart as a leader in the construction industry.

the Future, One Location at a Time

Geospatial Field Services

STAKING & LAYOUT

- Piers, Footings, Grade Beams

- Column Lines/Column Line Offsets

- Anchor Bolts

- Buildings

- Utilities (Above and Below Ground)

- Pavement/Curbs

- Clearing Limits, Silt Fence

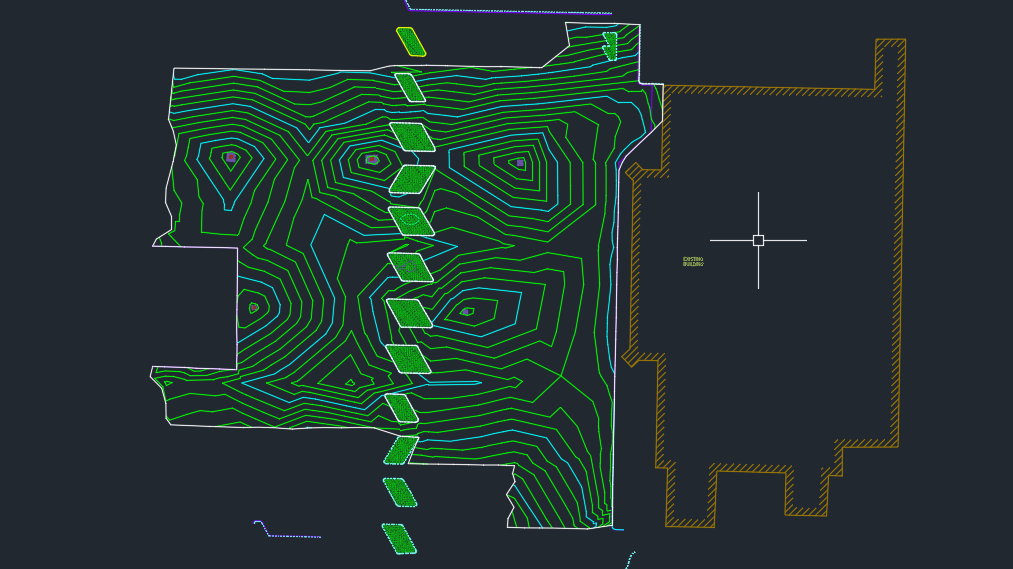

TOPOGRAPHIC

- Volumetric Surveys

- Contour Mapping

- Pre-Existing Conditions

- As-Built Locations

GPR CONCRETE SCANNING

Scan existing concrete up to 31” deep for location of rebar mesh, utilities/conduits placed in concrete, post tension cables, voids, and any other anomalies